Stable Development

The team started with four people in 2011 and grew to 110 by 2025, developing steadily and having a long history

Design and R&D Capabilities

4 hardware R&D engineers and 2 software R&D engineers.

After-Sales Service System

A complete after-sales service system, with professional after-sales engineers providing 24-hour remote service and on-site service

Channel Letter Bending Machine

In the modern advertising sign fabrication industry, precision, efficiency, and consistency directly determine product quality and production capacity. Whether producing channel letters, metal sign letters, signboards, resin signs, sign boxes, or custom logos, a Channel Letter Bending Machine has become an essential piece of equipment for professional sign manufacturers. It enables workshops and factories to handle complex shapes, multiple materials, and high-volume orders while maintaining stable quality standards.

A Channel Letter Bending Machine is a specialized CNC sign-making machine designed to automatically feed, groove, notch, and bend metal strips into precise letter shapes. These formed letter sides are then combined with face materials and backing to create illuminated or non-illuminated channel letters. Compared with manual bending, a channel letter bending machine significantly improves accuracy, reduces labor dependency, and shortens production cycles.

In today’s competitive signage market, investing in an automatic Channel Letter Bending Machine is no longer a luxury but a strategic necessity for scaling production and meeting client expectations.

The Channel Letter Bending Machine for advertising sign fabrication industry is widely used across multiple product categories:

Channel letters for storefront signage

All kinds of metal sign letters

Outdoor and indoor signboards

Resin signs with metal edges

LED sign boxes and light boxes

Brand logos with complex curves and angles

From retail chains and shopping malls to commercial buildings and urban landmarks, channel letter bending machines support the production of visually consistent, professional-grade signage.

One of the key advantages of a multi-material Channel Letter Bending Machine is its strong adaptability. Modern machines are engineered to handle a wide range of commonly used sign materials, including:

Stainless steel (mirror, brushed, painted)

Galvanized steel

Aluminum sheets

Aluminum profiles

Carbon steel

Copper and brass

Plastic strips

Channelume

A Channel Letter Bending Machine for stainless steel and aluminum ensures clean grooves and smooth bending, even for hard or reflective metals. This flexibility allows sign makers to expand their service offerings and respond quickly to diverse customer requirements.

Using a CNC Channel Letter Bending Machine transforms the entire sign fabrication workflow. Automated feeding, grooving, and bending reduce manual errors and material waste. Even complex fonts, sharp corners, and irregular logo outlines can be processed consistently.

Key efficiency benefits include:

Faster turnaround for bulk channel letter orders

Uniform letter depth and curvature

Reduced dependence on skilled manual labor

Lower scrap rates for expensive materials like stainless steel and copper

For factories handling overseas orders, a high-precision Channel Letter Bending Machine ensures repeatable results that meet international quality standards.

Brand signage demands visual consistency across multiple locations. A professional Channel Letter Bending Machine delivers accurate letter shapes based on CAD files, ensuring every logo and letter set matches design specifications exactly. This is especially important for franchise brands, chain stores, and large commercial projects.

By using a Channel Letter Bending Machine with CNC control, manufacturers can store bending programs and reuse them for repeat orders, improving both speed and consistency.

Whether you operate a small sign workshop or a large-scale manufacturing facility, a Channel Letter Bending Machine for sign makers can be configured to match your production needs. Compact models suit startups focusing on aluminum and channelume letters, while industrial-grade machines support high-volume stainless steel and galvanized steel production.

This scalability makes the channel letter bending machine a long-term investment for businesses planning steady growth in the advertising sign fabrication industry.

Modern signage is no longer limited to simple fonts. Curved logos, artistic letterforms, and customized shapes are increasingly common. A flexible Channel Letter Bending Machine allows designers to turn creative concepts into physical products without compromising accuracy.

By precisely controlling groove depth and bending angles, the machine supports both traditional channel letters and innovative metal sign letters with complex geometries.

For illuminated signage, structural accuracy directly affects lighting performance. A Channel Letter Bending Machine for LED channel letters ensures uniform side walls, which helps achieve even light diffusion and clean assembly. This is critical for sign boxes and illuminated logos where visual quality is closely inspected.

Investing in a reliable Channel Letter Bending Machine enhances production capacity, improves product quality, and strengthens competitiveness in the advertising sign fabrication industry. By supporting multiple materials, diverse applications, and automated workflows, the machine becomes a core asset for modern sign manufacturers.

As demand for high-quality channel letters, metal sign letters, and custom logos continues to grow, a Channel Letter Bending Machine for professional sign fabrication provides the technical foundation needed to meet market expectations and scale business operations sustainably.

In an industry driven by precision and efficiency, the Channel Letter Bending Machine remains one of the most important tools for transforming raw metal strips into impactful, brand-defining signage.

For more information about Laser And CNC Metal Processing Machines, please contact us!

Equipped with full servo control system to ensure the accuracy and stability of feeding, slotting, and bending function.

Manipulator alternately feeding structure, the material clamps are casted which can avoid scratching the matenial, mean while improving the feeding holding.

Productive: Cutting, Notching, Flanging, Bending & Shearing. All the functionl will short the letter making time.

Adaptable: can process all kinds of materials used in making sign letters, such as stainless steel, galvanized steel, flat aluminum, profile aluinum and channelume.

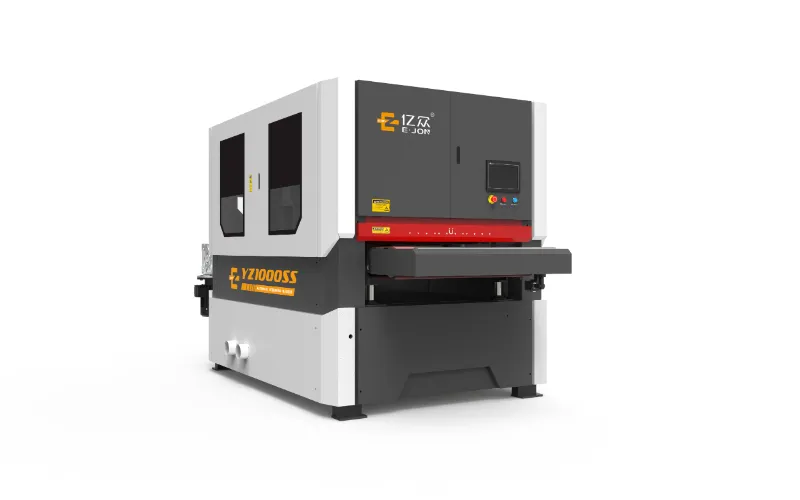

In the advertising sign fabrication industry, most quality issues do not originate from design or cutting accuracy, but from insufficient edge treatment and surface finishing. A Sanding Deburring Machine is not simply an auxiliary device—it functions as a core quality control process between cutting, bending, welding, and final assembly.

For manufacturers producing channel letters, metal sign letters, signboards, and logos, the sanding deburring machine directly determines whether a product is install-ready or becomes a rework risk.

Laser cutting, CNC punching, and plasma cutting inevitably leave micro burrs, sharp edges, and heat-affected zones. These defects may appear minor, but in real projects they often cause:

Poor welding strength

Uneven bending results

Coating adhesion failure

Scratches during transportation

Safety risks during installation

A Sanding Deburring Machine for sign manufacturing eliminates these hidden defects early in the production flow, ensuring downstream processes remain stable and predictable.

Unlike manual grinding, which depends heavily on worker experience, a Sanding Deburring Machine standardizes the finishing process. Each sheet or profile passes through the same abrasive pressure and brushing path, ensuring uniform edge radius and surface consistency.

For factories producing standardized channel letters or batch metal sign letters, this consistency is essential to maintaining stable output quality across large orders.

Different sign materials respond differently to cutting and bending. A multi-functional Sanding Deburring Machine allows manufacturers to fine-tune surface treatment based on material characteristics:

Stainless steel: removes laser slag without damaging surface finish

Aluminum and aluminum profiles: smooths edges while preventing deformation

Galvanized steel: protects zinc coating integrity

Carbon steel: prepares surfaces for painting or powder coating

Copper and brass: maintains decorative texture while removing sharp edges

Using a Sanding Deburring Machine for stainless steel and aluminum signage helps preserve material value while improving final appearance.

In channel letter production, unprocessed burrs often interfere with precise bending and fitting. A Sanding Deburring Machine for channel letters ensures clean edges before bending, allowing side walls to align correctly with faces and backs.

This directly improves:

Bending accuracy

Welding seam quality

Structural strength

Visual symmetry of finished letters

When paired with a Channel Letter Bending Machine, the sanding deburring machine forms a highly efficient and reliable production sequence.

Surface preparation is critical for painting, powder coating, electroplating, or brushing effects. A precision Sanding Deburring Machine creates a uniform micro-texture that improves coating adhesion and reduces peeling or bubbling over time.

For outdoor signboards, logos, and sign boxes, this process significantly extends product lifespan and reduces after-sales issues.

Many sign factories underestimate how much rework originates from poor edge finishing. Manual deburring often leads to inconsistent results, missed sharp corners, or excessive material removal.

A high-efficiency Sanding Deburring Machine minimizes these risks by delivering controlled, repeatable results. This reduces:

Secondary grinding

Material waste

Installation complaints

Project delays

Over time, the sanding deburring machine becomes a cost-control tool rather than an expense.

Custom logos, irregular fonts, and non-standard shapes are increasingly common in branding projects. A flexible Sanding Deburring Machine for custom signage handles complex contours more reliably than manual methods, ensuring every edge meets the same quality standard.

This capability allows sign manufacturers to confidently accept higher-value, design-driven projects.

Whether processing small batches or running continuous production, a Sanding Deburring Machine for advertising sign fabrication industry adapts to different throughput demands. From compact workshop models to industrial-scale systems, it supports long-term growth without compromising quality.

For manufacturers aiming to move from labor-intensive workshops to standardized production lines, the sanding deburring machine is a key transition tool.

In an industry where visual details define brand perception, edge quality is no longer optional. A professional Sanding Deburring Machine ensures that channel letters, metal sign letters, signboards, and logos leave the factory with clean edges, consistent surfaces, and installation-ready safety.

As customers demand higher finishing standards and faster delivery, the Sanding Deburring Machine becomes a decisive factor in maintaining reputation, efficiency, and profitability within the advertising sign fabrication industry.

For more information about Laser And CNC Metal Processing Machines, please contact us!

Application: remove solid slag and burrs on the surface of workpiece; remove rust and oxide layer on the surface of the workpiece; Round the internal and external contours at the edge of metal sheet.

Application: remove solid slag and burrs on the surface of workpiece; remove rust and oxide layer on the surface of the workpiece; Round the internal and external contours at the edge of metal sheet.

Supporting laser cutting machine, CNC stamping, various CNC processing or other machining deburring front production line.

Supporting laser cutting machine, CNC stamping, various CNC processing or other machining deburring front production line.

Metal fabrication industry

metal cutting,electrical switch manufacturing,aerospace, food machinery, textile machinery,engineering machinery, locomotive manufacturing Agriculture and forestry machinery, elevator manufacturing, special cars, household appliances manufacturing, tool processing, IT manufacturing, petroleum machinery manufacturing, food machinery, diamond tool welding, gear welding, metal material surface treatment, decoration advertising, laser external processing services and other machinery manufacturing and processing industries.

Industries: metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing Agriculture and forestry machinery

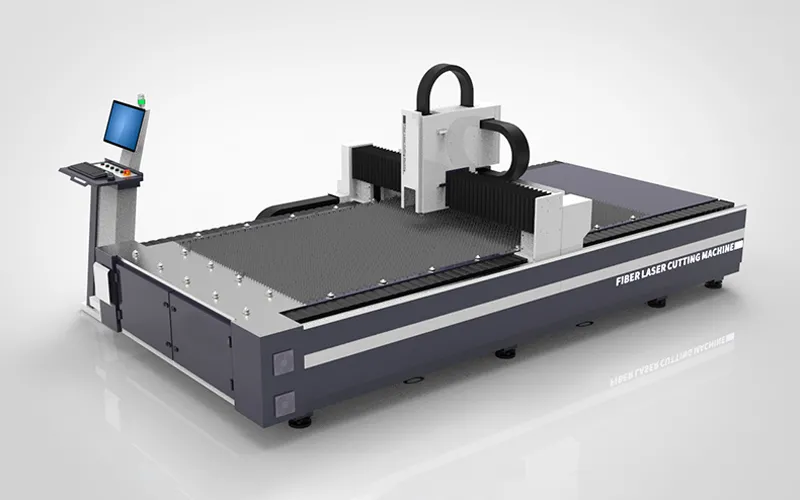

Across the global metal fabrication industry, manufacturers are under constant pressure to improve welding precision, production efficiency, and process stability. From metal welding workshops to highly specialized sectors such as aerospace, locomotive manufacturing, and IT manufacturing, the Automated Laser Welding Machine has become a core piece of intelligent equipment driving industrial upgrading.

By combining high-energy laser sources with CNC automation and precise motion control, an automated laser welding machine delivers consistent weld quality that traditional welding methods struggle to achieve.

An Automated Laser Welding Machine is an advanced welding system that uses focused laser beams to create deep, narrow weld seams with minimal heat input. Integrated automation allows the machine to perform continuous, repeatable welding operations with minimal human intervention.

Compared with manual TIG or MIG welding, an automated laser welding machine offers higher precision, faster welding speeds, and superior consistency, making it ideal for both mass production and high-value manufacturing environments.

In general metal welding applications, an automated laser welding machine ensures stable penetration and clean weld appearance. The controlled heat-affected zone reduces deformation, allowing manufacturers to maintain tight dimensional tolerances even on thin or complex metal components.

This makes automated laser welding especially suitable for industries requiring both strength and aesthetic quality.

The Automated Laser Welding Machine for metal fabrication industry is widely applied in a broad range of sectors:

Electrical switch manufacturing, where precision and repeatability are critical

Aerospace manufacturing, requiring high-strength, low-defect welds

Food machinery manufacturing, where smooth, hygienic weld seams are essential

Textile machinery and engineering machinery fabrication

Locomotive manufacturing and special vehicle production

Agriculture and forestry machinery welding

Elevator manufacturing and structural components

Household appliances manufacturing with thin metal parts

Tool processing and diamond tool welding

Gear welding and precision transmission components

IT manufacturing with micro and fine weld requirements

Petroleum machinery manufacturing with high-strength weld demands

Metal material surface treatment and secondary processing

Decoration advertising and metal signage fabrication

Laser external processing services for diversified client orders

This versatility makes the automated laser welding machine a universal solution across machinery manufacturing and processing industries.

An Automated Laser Welding Machine delivers a combination of technical and economic benefits:

High welding speed for increased production output

Narrow weld seams with excellent appearance

Minimal thermal distortion and reduced post-processing

Strong and consistent weld strength

Easy integration into automated production lines

These advantages allow manufacturers to meet strict quality standards while maintaining cost efficiency.

In industries such as aerospace, IT manufacturing, and electrical switch manufacturing, welding accuracy directly affects product performance. A high-precision Automated Laser Welding Machine ensures exact seam placement and repeatable weld depth through CNC control and automated positioning.

This level of control supports intelligent manufacturing strategies and reduces reliance on skilled manual welders.

A multi-material Automated Laser Welding Machine is capable of welding various metals commonly used in fabrication industries, including:

Carbon steel and alloy steel

Stainless steel

Aluminum and aluminum alloys

Copper and copper alloys

Galvanized metals

The ability to handle different materials makes the automated laser welding machine suitable for diverse production lines and contract manufacturing services.

In food machinery manufacturing, weld quality affects both safety and compliance. An automated laser welding machine produces smooth, clean weld seams with minimal spatter, reducing contamination risks and simplifying cleaning processes.

This makes laser welding technology particularly valuable for equipment used in food processing environments.

For engineering machinery, petroleum machinery, and special vehicles, weld strength and reliability are critical. A heavy-duty Automated Laser Welding Machine ensures deep penetration and strong metallurgical bonding, supporting long-term structural durability under harsh operating conditions.

Laser external processing service providers benefit significantly from an Automated Laser Welding Machine. Its flexibility allows quick changeover between different products and industries, enabling service centers to handle small batches, customized components, and high-precision orders efficiently.

This flexibility increases service capacity and expands potential customer markets.

As manufacturing moves toward automation and intelligent production, the Automated Laser Welding Machine represents a long-term investment in quality, efficiency, and competitiveness. By reducing labor dependence, improving weld consistency, and supporting a wide range of industries, it becomes a cornerstone of modern metal fabrication systems.

From aerospace and locomotive manufacturing to decoration advertising and household appliances, the Automated Laser Welding Machine continues to redefine welding standards across the metal fabrication industry, enabling manufacturers to meet higher expectations while scaling production sustainably.

For more information about Laser And CNC Metal Processing Machines, please contact us!

YAG laser transmission welding, 5 meter fiber optic tube, high temperature resistance handheld laser welding handheld.

Handheld fiber optic welding machine, equipped with the latest generation of laser generators and our company'sdeveloped swinging welding head.

Customized for the aluminum letter adverising industry, it uses a stable laser generator with a lifespan of up to 100,000 hours.

Metal fabrication industry

metal bending,electrical switch manufacturing,aerospace, food machinery, textile machinery,engineering machinery, locomotive manufacturing Agriculture and forestry machinery, elevator manufacturing, special cars, household appliances manufacturing, tool processing, IT manufacturing, petroleum machinery manufacturing, food machinery, diamond tool welding, gear welding, metal material surface treatment, decoration advertising, laser external processing services and other machinery manufacturing and processing industries.

New rigid design and finite element optimization analysis minimize the impact of bending deformation on workpiece quality.

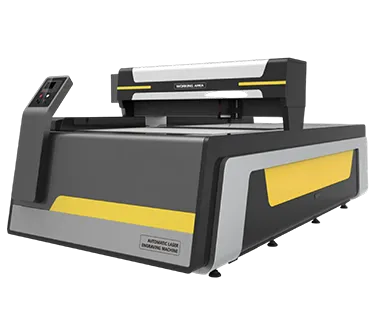

CO2 laser cutting machines are primarily designed for cutting and engraving non-metal materials, offering high precision and efficiency in various industrial applications. For non-metal substrates, they efficiently handle acrylics (also known as plexiglass or PMMA), plywood, papers, plastics like ABS, PVC, PETG, nylon, and polypropylene, as well as leather, fabrics, rubber, MDF (medium-density fiberboard), and bamboo.

Additionally, they support engraving laminates, mylar, and woods, making them ideal for signage, packaging, and educational projects

It adopts flight light path design, with unique structure, small light path deviation, high stability and convenient adjustment.

Tianjin Ejon Flying Science And Technology Co., Ltd

Tianjin Ejon Flying Science and Technology Co.,LTD. is specialized in the production of CNC automation equipment. The company has independent intellectual property rights. Since the company was established with excellent design concept and perfect service system, prompt set up for an integrated hightech advertising equipment manufacturers that with a collection of design research and development, production and sales-services.

13,000

Market Holding Capacity

42+

Export Countries and Regions

18

There are Fixed Partners

in 18 Countries and Regions

110+

Number of Employees

Excellent machine, very fast and accurate, Special thanks to Ada Zhou, she is a very attentive and responsible manager.Excellent machine, very fast and accurate, Special thanks to Ada Zhou, she is a very attentive and responsible manager.

Better than what I expected.

Bending machine

In time delivery, good quality machine, easy to use, easy design and good service

Lisa

Dealer

Bruno

Dealer

Jake

Dealer

Adela

Dealer