Service

Pre-sales Service

Needs Analysis

Free technical consultation, recommending suitable machine models based on the material being processed (stainless steel, carbon steel, aluminum alloy, etc.)

On-site sampling service: Workpieces can be brought to our lab for verification of processing results.

Equipment selection charts are provided, clarifying the thickness range (0.5-20mm) and processing efficiency (5-25 m/min) for different models.

Special Needs Response: Customized equipment can be tailored to meet specific customer requirements.

Mid-sale Service

Delivery Implementation

Guidance on all preparatory work before equipment arrival

Provide 3D installation instructional videos and printed manuals

On-site installation and commissioning by professional engineers

Training system

Basic operation training: covering equipment installation, startup self-test, commissioning, proofing, etc.

Advanced maintenance training: covering mechanical maintenance, sensor calibration, etc.

After-sales Service

Quick Response

24/7 Technical Hotline (400-999-3006)

Remote Diagnosis System

On-site Maintenance

Value-Added Services

Process Upgrade Service: Annual Process Optimization Report

Parts

The entire machine is under warranty for one year. Parts damaged by non-human factors will be replaced free of charge during the warranty period, and the warranty period will be recalculated for the new part.

The company provides spare parts throughout the machine's lifecycle.

Transportation and Logistics Services

Based on customer needs, we offer the following:

01

One-stop transportation and customs clearance: We arrange domestic, ocean, and international shipments, with door-to-door delivery.

02

We can ship goods to any port in mainland China or to a designated shipping address as required.

03

We pre-register HS codes and provide certificates of origin to help customers save on import duties and other costs.

04

EU Conformity Certification

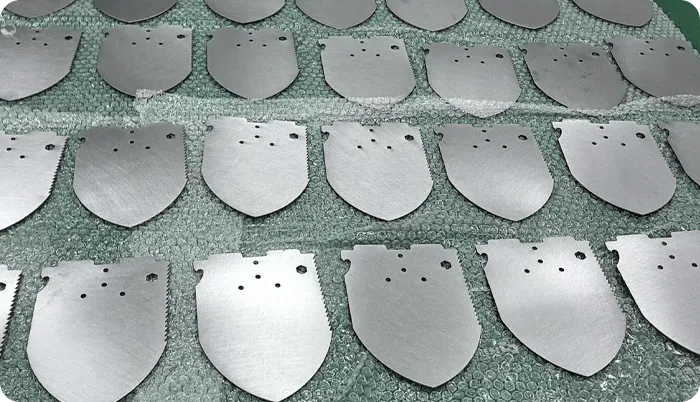

Cooperation Case